Are RENEWABLE Ships a Possibility?

- Shashank Shekhar Tiwari

- Dec 12, 2020

- 8 min read

The road to carbon neutral world is a long and hard way ahead, it will take 10s of years for humans to be free from fossil fuels and move towards future with renewables and other forms of energy. If we look at the world today and compare it to 1940s, we can clearly see a change of over 90% in the amount of CO2 emissions. A study by CDIAC done in 2017 showed the difference in carbon emission from 1940s to 2017, the difference is drastic and not in the favor of our planet. as of 2018 as much as 77% of CO2 emissions is due to energy (Transportation-29%, Commercial and Residential-12%, Electricity-28%, concrete-8%), 9% coming from agriculture and 14% from industry. Out of this as much as 2% of this emission comes directly from the shipping industry. Though it does not seem to be very big but when converted to the amount of emission it amounts to over 930 million tons of carbon emission each year which is over 90000 tonnes/hr or 25 tonnes/sec. International shipping alone contributed around 812 million tonnes which is 282 million tonnes higher when compared to emissions from international aviation. This number might not be that big when compared to road transport but is still very big and it is expected to increase by 50% to 250% by 2050 leading to rise earths temperature by 1.5 degrees.

Road transport is working its way towards carbon neutral future and so are the other industries, they are working towards making a carbon neutral future by using new ingenious and novel technologies. One of those industries is the shipping industry which amounts to around 2% of the global green house gas emission. The vast majority of this is created by container ships which carry over 80% of the worlds trade. Astoundingly there aren't missions of ships hauling our commodities across the world; Maersk, the worlds largest shipping company carries 17.6% of the worlds cargo container transport, only has 786 ships (786 gigantic ships). This ships will last 20-30 years, so its important to convert these ships to carbon neutral technology when the time comes. The largest ship in the Maersk fleet, the Maersk EEE is about 400m in length and can carry 20000 standard(20 feet) size containers.

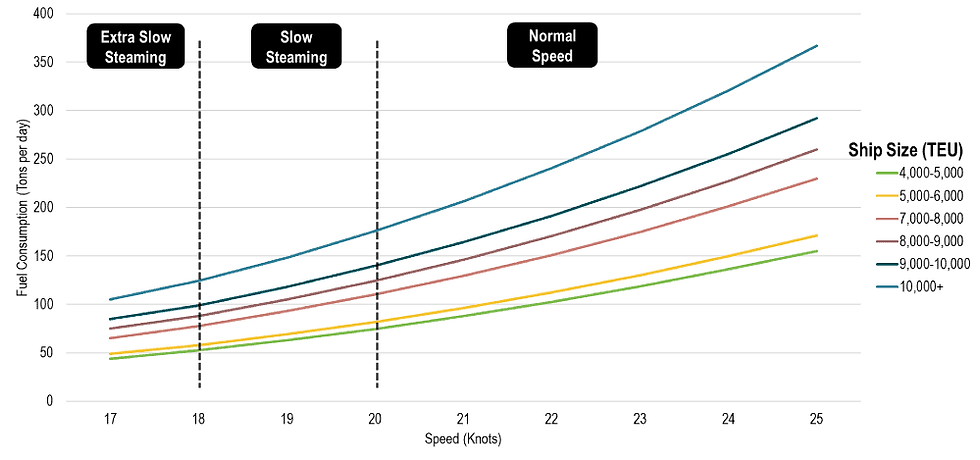

Its easy to see the impact of these polluting monsters on the environment, each of these ships have an astounding impact on the global emissions. Maersk alone release over 36.5 million tons of CO2 in 2019 alone, roughly equivalent to a small countries emission, like Ireland. To give credit, the cargo ships are astoundingly much more efficient then any other mode of transport (CO2/tonne transported per Km- Maersk EEE-3g, Rail-18g, Diesel Truck-47g, Air Freight-550g). This figure was closer to 6g in 2007, but Maersk did not invent some revolutionary technology to achieve this, they just slowed down. Fuel consumption of these ships is primarily a combination of their size, weight and speed. The graph below shows the fuel consumption per day at different relative speeds.

The fuel consumption of these ships rises exponentially with each knot of speed added and the heavier the ship, the more pronounce that fuel increase is. For example a 8000 TEU moving at 24 Knots would be expected to burn at least 225 tonnes of fuel per day but a reduction in speed by just 12.5% to 21 Knots will result in a 33% decline in fuel consumption to 150 tonnes/day. The practice of reducing speed began in 2007 not because of climate change concerns but as a result of rising fuel prices and then by 2008 the practice of fortified by the arrival of financial crises placing financial strain on the world economy. To survive and reduce costs, shipping companies looked towards lower fuel consumption and the trend continues today as the climate change came into focus. That 32% reduction is great but getting to 60% by 2030 and 100% by 2050 as Maersk aims to do wont be easy. Slowing down a ship for fuel consumption is a game of diminishing returns, below 12-15 Knots and it just doesn't make sense and to achieve 100% with this method, we would just need to turn off our engines, a good way to collapse the world economy. So whats the plan to get to 100% ? To tackle this many solutions have been proposed, like use of batteries and solar power, bio-fuels and wind.

The Rise Of Renewable shipping

Something interesting happened when these ships started to slow down; their carefully shaped hulls stopped working as designed. The hulls of huge ships are carefully designed to minimize drag but at a particular operating speed, lowering the speed of the ships messed with the fluid dynamics and prevented some drag reducing designs from working properly. For example the Bulbous Bow alone reduce the drag by 15% at a design speed, this technology reduces the energy that is being lost to wave creation and also reduces frictional drag as the contact area the ship has with the water is reduces. The range of a typical ship in 2007 was pretty narrow, today the speeds are not only lower but they are far more variable. Bows that were designed for higher speeds will simply not function at lower speeds. So, as part of Maersk's fuel saving efforts they started retrofitting their Bulbous Bows for once better suited for new lower operating speeds in 2012.

Getting an industry like this to clean up their acts start by increasing their efficiencies. With a machine this large, efficiency has to be our primary focus in lowering emissions. Its low hanging fruit but can as we have seen result in saving millions of tonnes of fuel being saved. There are a huge number of technologies being developed with this goal in mind. One particularly interesting shift that we are seeing in the industry is the return of wind power, to offer additional thrust to these massive ships. A centuries old technologies that once powered shipping empires like the Dutch, West India company. Its difficult to integrate wind power into our modern ships, shipping companies wont integrate them if they take up too much space which could be used for cargo, and designing them in a manner that allows for a timely return on investment is difficult. One particularly interesting form of wind power is currently being tested is the Flettner Rotor, these rotors use the Magnus Effect to generate thrust, which is a force experienced by a rotating object as a result of the deflecting air around it, when presented with a cross wind. These rotors can provide a good deal of thrust for very little energy input. Modern composite materials have allowed the rotor to be much lighter and thus take less power to spin. According to Nors Power, their largest rotor can provide up to 3MW of forward thrust for just 90KW of electricity. Critically, they are simple in construction and minimizing cost, they take up minimal space on deck, minimizing loss of revenue, can be easily retrofitted on many types of ships and the rotors are controlled by computers, requiring little to no input from the ships crew. These rotors are being currently tested on a Maersk tanker and between Sept. 2018 - Sept. 2019 saved 8.2% of their fuel, if that is repeatable, we can't imagine it would be long before we see these devices fitted to more ships on routs with favorable prevailing winds. Of course wind isn't going to power these ships on its own, we can only get fuel consumption so low and this is were shipping industry faces its biggest challenge, Fuel!

One of the concepts for reducing the fuel consumption is developed by a company called Skysails for large ships, whose inflatable kites fly between a 100m-300m above the sea level where wind speeds are higher. This is because the friction between air near the water surface slows down air. When the kite is in air an automatic control system keeps it flying at the most optimal angle which helps in providing a 5% reduction in energy consumption when doing mixed routes and around 12% for more favorable routes. And during the best conditions for the kite, it managed to provide 50% power for the propulsion per hour for a 10000 tonnes cargo ship it was attached to(MS Beluga Projects).

Another prototype in testing is the Airfoils, which is similar to the conventional sails and a combination of three technologies and a prototype is being prepared by the name of Oceanbird is in progress. A project on this technology done at the Tokyo University called the UT Wind Challenger gave us some inside of the ships working. The airfoils on the bow are telescopic and work like the wings of a plane, redirecting the airflow to create a pressure difference and create lift. Technically the optimal wind direction is from the side as it allows all the airfoils to be utilized, whereas a tail wind means all the airfoils work as one. This system has yet to be tested on real ships; however, simulations found that on the North American circle route, the energy consumption can be reduced by 23% and if a more optimal route for the wind is chosen, this could increase to 30%.

Traditionally, the shipping industry has used this horrible pollute of heavy sludge like fuel, literately bottom of the barrel quality fuel, cheap but incredibility dirty, releasing heavily pollutants like Sulpher, and Nitrous Oxide into the atmosphere. The International Maritime Organization(IMO), mandated that these emissions need to be reduced and the shipping industry has primary responded by turning to low Sulpher heavy fuel oil, fitting scrubber systems to remove the pollutants from the exhaust while others are turning to Liquefied Natural Gas(LNG). The largest LNG ship, launched just 3 months back, which would all but eliminate many of the problems associated with heavy fuel oils and result in about 20% less carbon emission but they are leaking a large amount of Methane into the atmosphere, a much more potent greenhouse gas. At the end of the day, this fuel is a fossil fuel, we could switch to bio-fuels, like bio-gas or bio-diesel, these are both derived using normal renewable methods of coverting biomass into fuels nut their ability to eliminate carbon emissions are debatable, some methods reduce the net CO2 output and others are worst for the environment then fossil fuels. Bio-fuels like bio-diesel are less carefully regulated are completely pointless and could just encourage more of woodland areas into agricultural farmlands to grow soybean while barely reducing our carbon emissions.

Another interesting technology being worked upon is the use of solar panes. A project names Aquarius ECO Ship is an ongoing comprehensive, study focused project by ECO Marine power in Japan. The design is focused on on the use of solar panels along with energy sails(sails build out with solar panes) on the sides of the ship. Though it is still in the initial stages of R&D, it could turn out to be one of the major project to go to the deployment stages in the near future due to its innovative approach to solving both the problems of wind and solar.

Thankfully,the shipping industry is already pretty efficient but there is always room for improvement, this will take investment and will cut into the shipping industries profits as fuel prices rise but these are necessary moves that will not only reduce but will eliminate our carbon emissions. As we saw, the only reason the shipping companies began to move away from heavy fuel is because the IMO mandated it. We need to put pressure on the companies to not only clean up their technology but be ready for the next step. These are big machines that will be sailing our oceans for decades, making the wrong move now and betting on the wrong fuel that isn't ultimately better for the environment and isn't scalable is a problem we will have to live with for decades. We need to be future focused and need to make the right decisions today. The shipping industry is the backbone of our modern day world, shipping products from all over the world, from food to fuel. The modern economy will simply come to halt without their services.

Comments